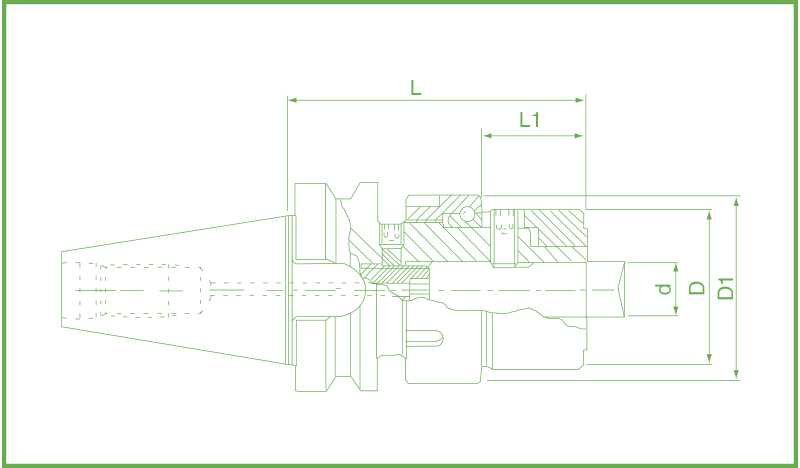

µmatic High Precision Chucks

Increase Productivity At An Economy Price With The Unique Precision Chuck From CENTAUR

The µmatic high precision chuck is designed specifically to meet the demands of today’s new generation of machines and cutting tools. µmatic’s powerful clamping force and ability to hold tools within 50 millionths T.I.R. eliminate the need for expensive hydraulic chucks and conventional milling chucks.

Centaur’s innovative µmatic chuck features clamping surfaces ground directly from the toolholder body. Holding a cutting tool within 0.0002” T.I.R. is achieved with no adjustments.

µmatic incorporates truing screws that contact the tool shank directly, permitting rapid adjustments to within 50 millionths — either on a presetter or in the machine spindle.

µmatic is ideal for rough milling and finish milling. And because of µmatic’s unusually high accuracy, it is perfectly suited for holemaking applications that normally require hydraulic chuck or boring operations.

The µmatic high precision chuck ensures greater workpiece accuracy, while delivering increased feed rates and tool life.

The bottom line: Increased productivity.

Features and Benefits:

- PATENTED, VIBRATION-DAMPING STRUCTURE. Centaur’s µmatic interrupts the transmission of helical vibrations to allow increased RPM and feed rates.

- GUARANTEED HIGH ACCURACIES. Tools clamp within 0.0002” T.I.R. with no adjustment. Truing screws that contact directly to the tool shank can be set easily and quickly to achieve T.I.R. within 50 millionths.

- IDEAL FOR TODAY’S FINEST MACHINE TOOLS. µmatic is balanced to 22,000 RPM and is sealed for coolant-through applications.

- LOCKING SCREW. In addition to exerting extremely powerful clamping forces, the µmatic high precision chuck is equipped with a Weldon type screw to eliminate tool pullout common with standard heavy duty milling chucks.

- DELIVERY FROM STOCK. µmatic chucks are shipped directly from Centaur’s huge U.S.-based inventory in all standard sizes. CAT/V-Flange, BT and HSK shanks are available. 40 taper toolholders have a capacity to 1-1/2” endmills; 50 taper to 2”.

- VALUE PRICING. µmatic high precision chucks can replace expensive hydraulic chucks and heavy duty milling chucks, yet are available from Centaur at a fraction of the cost.

CAT/V-FLANGE SPECIFICATIONS

|

|

|||||||||||||||||||||||||||||||||||||||||

BT SPECIFICATIONS

|

|

|||||||||||||||||||||||||||||||||||||||||

HSK SPECIFICATIONS

|

|

||||||||||||||||||||||||||||||