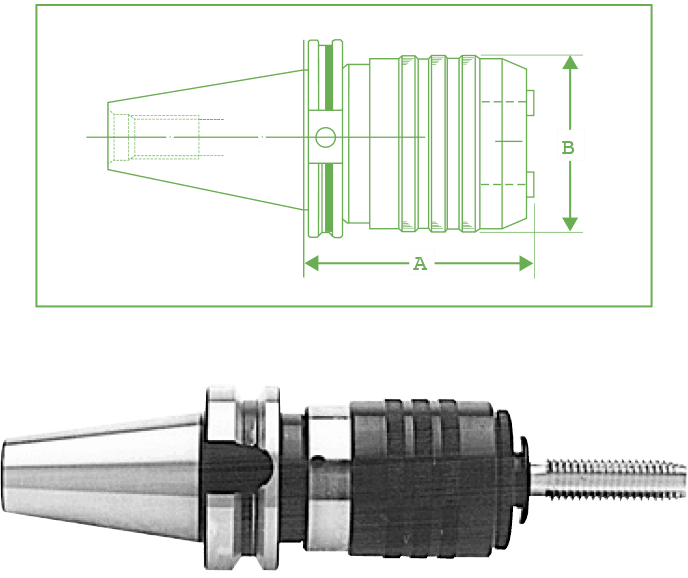

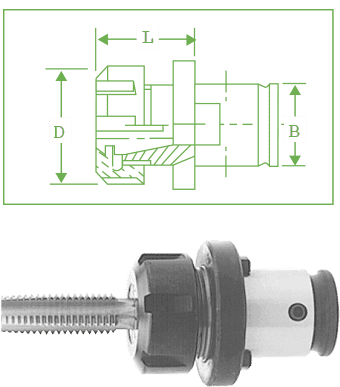

TAPER – SHANK TAP HOLDERS

RIGID TAP HOLDERS

TENSION-COMPRESSION TAP HOLDERS

|

|

||||||||||||||||||||||||||

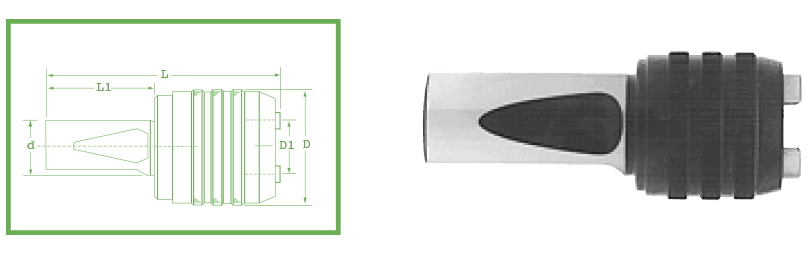

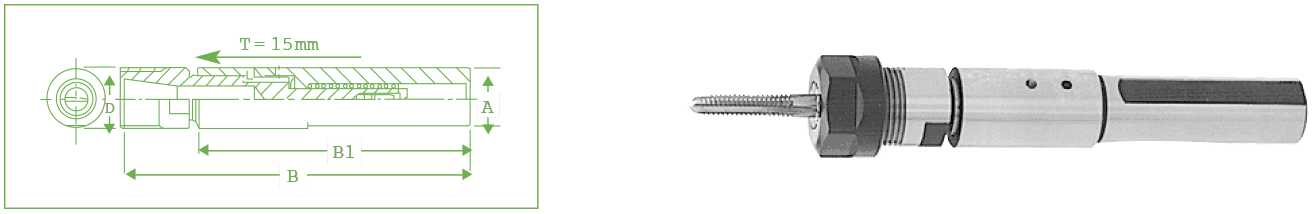

STRAIGHT – SHANK TAP HOLDERS

RIGID TAP HOLDERS

RIGID TAP HOLDERS

|

|

||||||||||||||||||||||||||||||||||

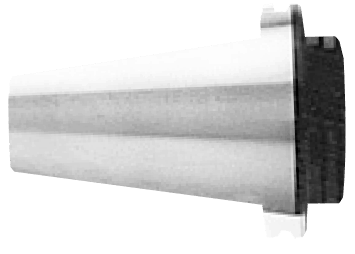

TAP HOLDER SHANKS

|

|

|||||||||||||||

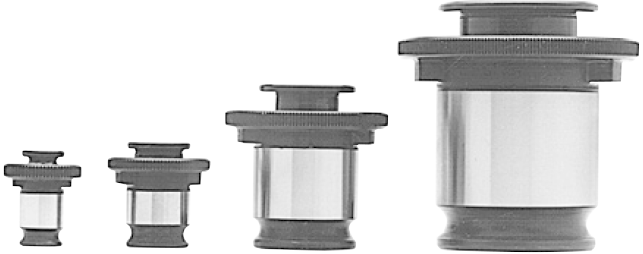

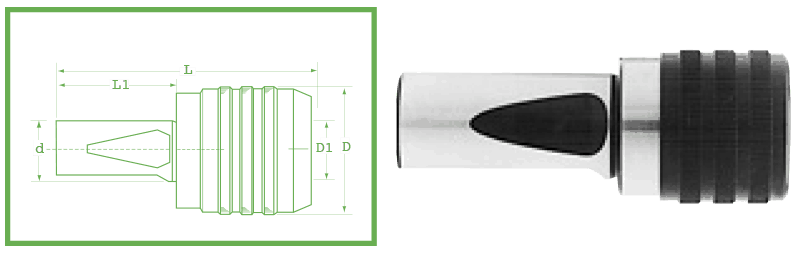

POSITIVE – DRIVE TAP ADAPTERS

- Fully interchangeable with Bilz and other popular tapping systems

- Engineered for smooth operation and easy release

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

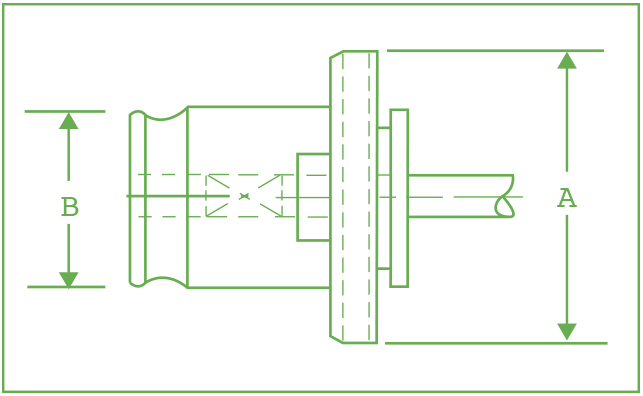

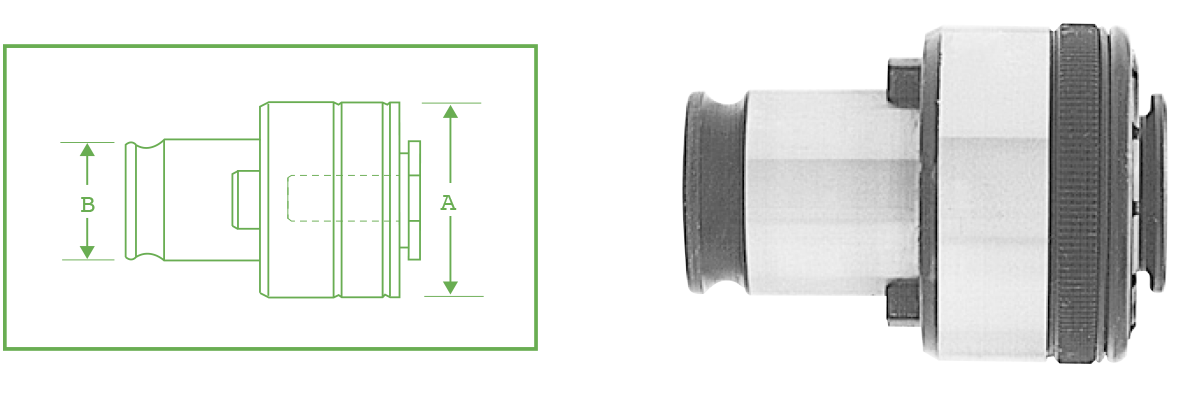

TORQUE CONTROL TAP ADAPTERS

TAP ADAPTER

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | B | |

| CWES 0 CWES 1 CWES 2 CWES 3 CWES 4 |

0.91 1.26 1.97 2.84 3.74 |

0.51 0.75 1.22 1.89 2.37 |

| Hand Tap Size | Part No. CWES 0 |

Part No. CWES 1 |

Part No. CWES 2 |

Part No. CWES 3 |

Part No. CWES 4 |

| 0-6 8 10 12 1/4 |

001006 001008 001010 001012 001250 |

101006 101008 101010 101012 101125 |

|||

| 5/16 3/8 7/16 1/2 9/16 |

101312 101375 101437 101500 101562 |

201312 201375 201437 201500 201562 |

|||

| 5/8 11/16 3/4 |

201625 201687 201750 |

||||

| 13/16 7/8 |

201812 201875 |

310812 310875 |

|||

| 15/16 | 310937 | ||||

| 1 1 – 1/8 1 – 1/4 1 – 3/8 |

311000 311125 311250 311375 |

411000 411125 411250 411375 |

|||

| 1 – 1/2 1 – 5/8 1 – 3/4 1 – 7/8 |

411500 411625 411750 411875 |

| Pipe Tap Size | Part No. CWES 1 |

Part No. CWES 2 |

Part No. CWES 3 |

Part No. CWES 4 |

| 1/8 – SS 1/8 – LS |

101062 101063 |

|||

| 1/4 P | 201126 | |||

| 3/8 P 1/2 P |

201376 201501 |

311037 311050 |

||

| 3/4 P 1″ P |

311075 311100 |

415750 4151000 |

||

| 1 1/4 P 1 1/2 P |

4151250 4151500 |

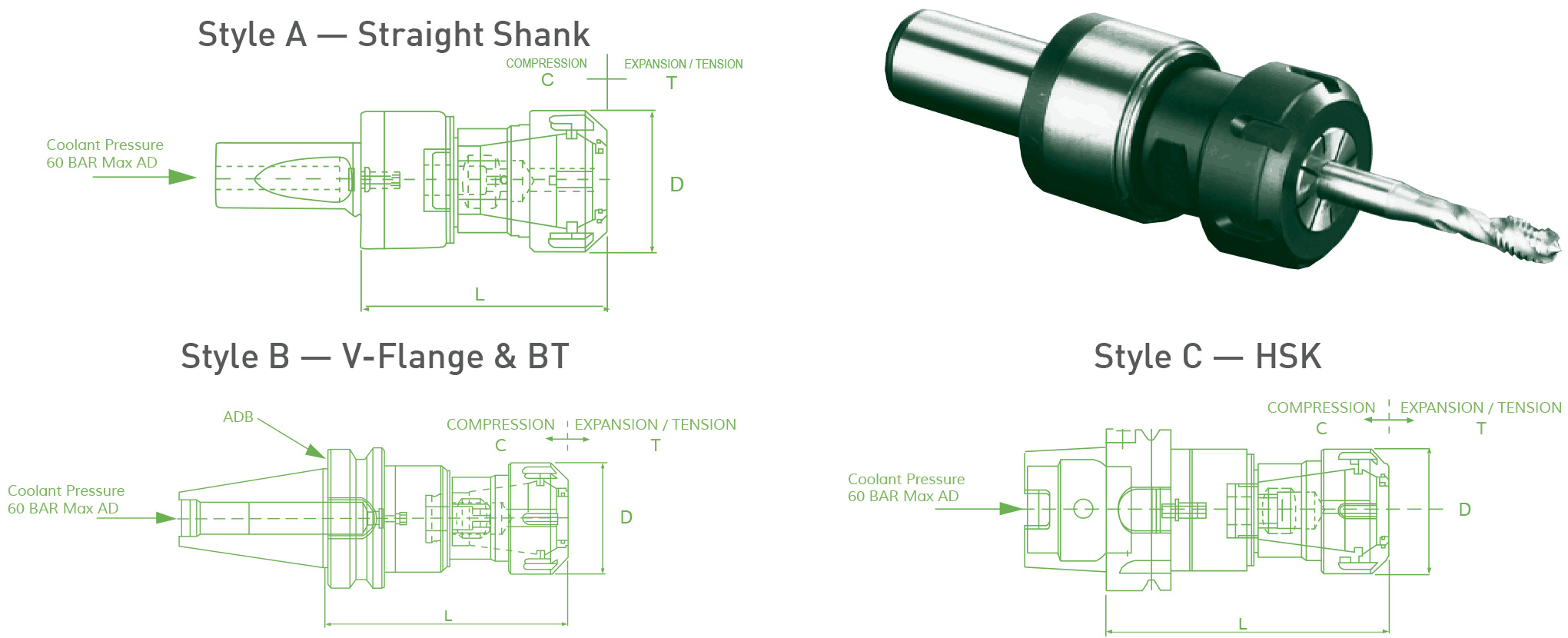

QUICK-CHANGE COOLANT-THROUGH TAP HOLDERS

|

Uses STANDARD TAP ADAPTERS for oilhole taps in blind hole applications. |  |

Uses EXTERNAL COOLANT FLOW ADAPTERS for standard taps in blind and throughhole applications. |

|

TAPER SHANKS

|

|

||||||||

STRAIGHT-SHANK

|

|

||||||||||||||

EXTERNAL COOLANT FLOW TAP ADAPTERS

|

|

||||||||||||||||

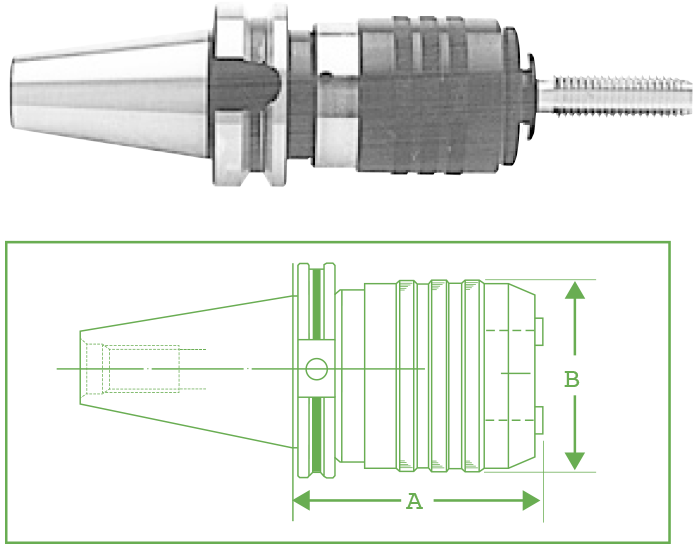

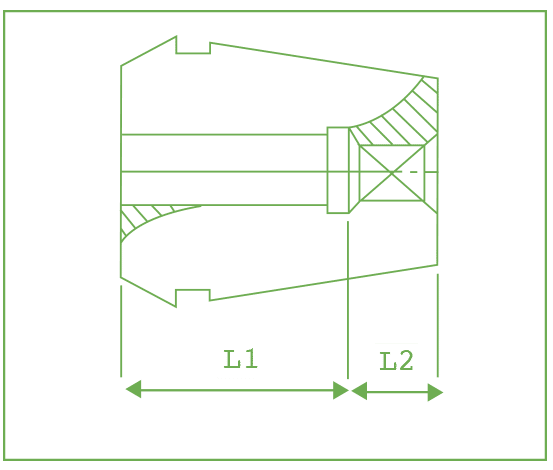

CENCHRO TAPPING CHUCKS

A new Tapping chuck to maximize efficiency and lower costs in all Rigid Tapping or Synchronous feed Tapping applications.

In theory; with a rigid tapping application the machine keeps the relationship between feed rate

and rotational forces timed perfectly. Any deviation in the feed rate in relation to the RPM creates unnecessary wear on the tap causing poor tap life and inaccurate tapped holes. The new technology built into the CenChro Tapping Chucks compensates for the minute discrepancies between the machines feed rate and RPM throughout the entire tapping cycle. CenChro Tapping Chucks have 0.5mm controlled movement in the tension and compression modes to compensate for minute deviations and allow the tap to be influenced only by rotational force, and produce gage perfect threads with depth repeatability.

Increase productivity with the new CenChro Tapping Chucks by reducing downtime for tap changes, increased speeds and higher quality tapped holes.

CenChro Tapping Chucks use RTS Tapping Collets and RTS Sealed Tapping Collets for coolant through applications.

|

||||||||||||||||

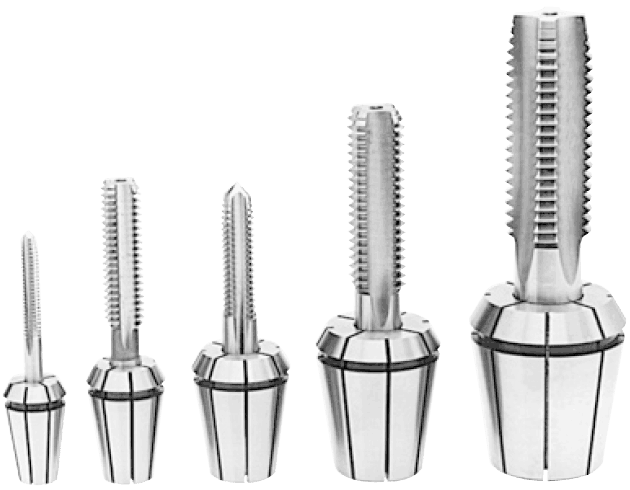

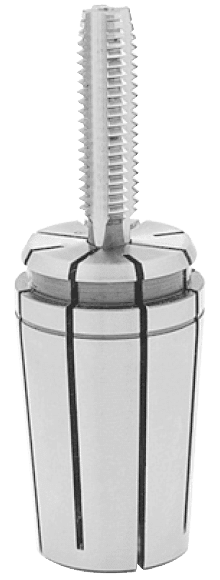

RD/ER RIGID TAPPING COLLETS WITH SQUARE DRIVE

- Collet bore is exactly tool diameter for accuracy and rigidity

- Permit synchronous tapping operations using any standard collet chuck

- Available sealed for coolant-through applications

NOTE: Metric, DIN and Japanese standard sizes on request.

|

|

|||||||||||||||||||

|

|

|||||||||||||||||

|

||||||||||||||||||

RDG/TG RIGID TAPPING COLLETS WITH SQUARE DRIVE

- Collet bore is exactly tool diameter for accuracy and rigidity

- Permit synchronous tapping operations using any standard collet chuck

- Available sealed for coolant-through applications

NOTE: Metric, DIN and Japanese standard sizes on request.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

RDT AXIAL COMPENSATING TAPPING COLLETS

- RDT Tapping Collets permit tapping operations using standard RD/ER collet holders

- Quick-change tap removal with solid square drive. Allows tap replacement without removing the tap collet from the chuck, while maintaining consistent tap gage length

- Friction-free ball bearing drive with axial compensation. Helps deter tap breakage on machines with synchronous feed or machines requiring axial compensation

NOTE: Metric, DIN and Japanese sizes available upon request. |

|

|||||||||||||||||||||||||||||||||

BF ADAPTERS FOR RD/ER COLLETS

- Quick-change adapters are interchangeable with Bilz and other popular tapping systems

- Collets permit holding ANSI and metric sizes

- Can be used for tapping and drilling

*NOTE: Available upon special request |

|

||||||||||||||||||||||||

FLOATING TAP HOLDERS

- Permits tapping using RD/ER 16 collet system

- Ideally suited for applications on Swiss and Japanese automats and lathes

|

||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||

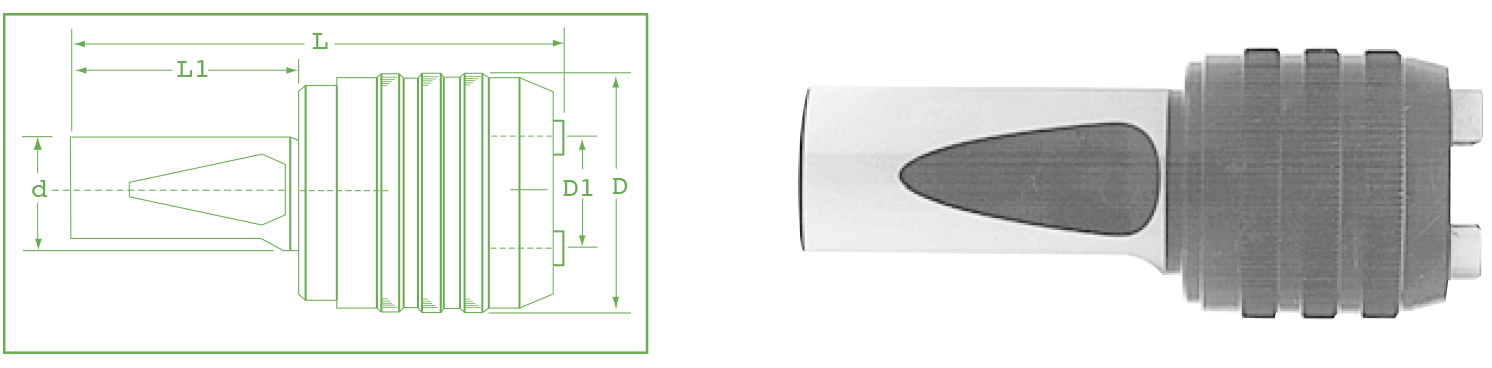

CCSPL ALL-PURPOSE TAPPING ATTACHMENT

For tapping operations on reversible drilling and tapping machines, lathes, mills, and others.

- Safety chuck

- Radial parallel float

- Length compensation

PRODUCT FEATURES

PRODUCT FEATURES

The Centaur CCSPL provides a wide-range, twin chucking head for the direct clamping of taps. There is no need for separate collets. An adjustable safety torque clutch helps prevent tap breakage. Radial parallel float compensates for misalignment between hole and tap. Length compensation on compression and tension compensates for the difference between machine feed and tap pitch.

Safety Torque Clutch. The safety clutch is infinitely variable to the required tap size torque by simply adjusting to scale. The safety clutch disengages when the preset torque is exceeded. After disengagement, there is virtually no torque on the tap, minimizing clutch wear. This prevents tool breakage. Blind holes can be bottom tapped under full rotation of the spindle. Reversing the spindle, the clutch reengages and the tap is automatically withdrawn.

Radial Parallel Float. This ball-bearing float device guarantees threads to exact tolerance. It also protects misaligned taps against side thrust. It automatically centers after every tapping operation.

Length Compensation. Ball-cage length compensation provides smooth axial movement, even in the presence of maximum torque. This free axial movement prevents damage to thread flanks when the feed rate and tap pitch do not match. It also permits cutting small threads on heavy machines.The length compensation positions at zero point and is therefore also suitable for machine feed.

NOTE: CCSPL tapping attachment is suitable for right-hand threads only. For left-hand threads on request.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

PRODUCT FEATURES

PRODUCT FEATURES